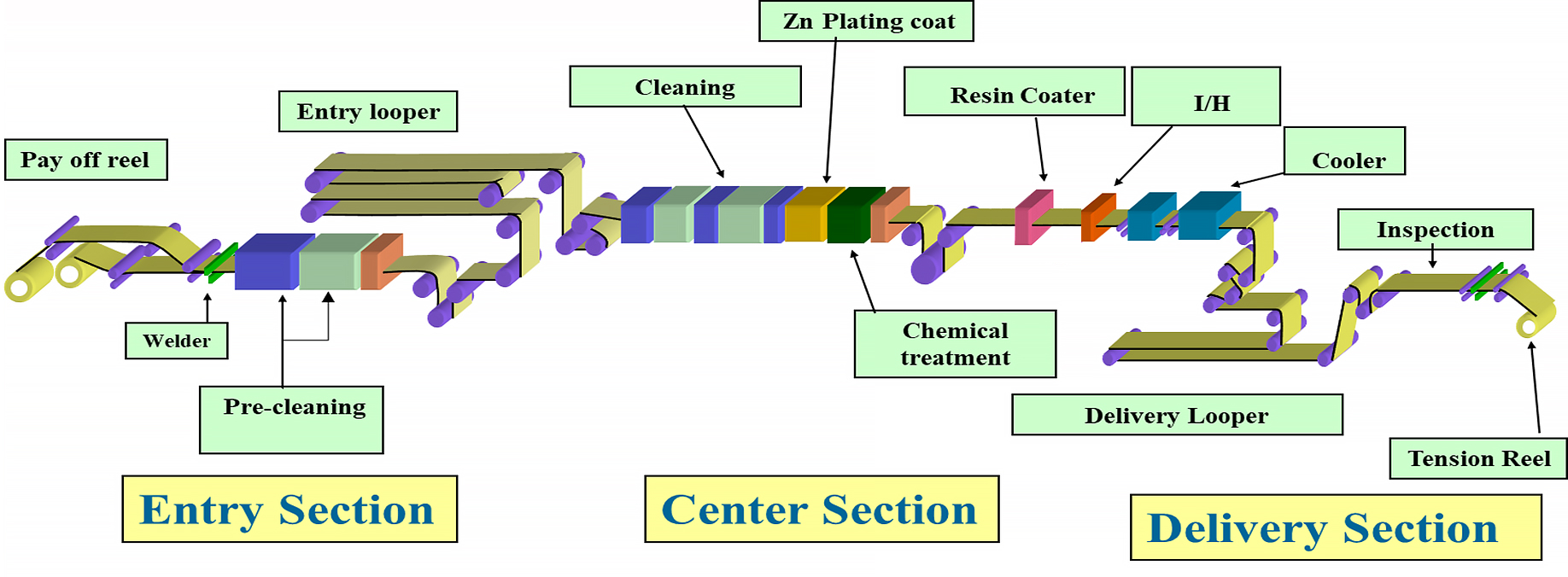

Outline of TCS Process

TCS line process is composed of three sections, entry, center and delivery section. Below the outline of TCS is shown.

ENTRY SECTION

- Feed cold rolled sheet into the center section continuously

- 1. Pay off reel : Two pay off reels to feed cold roll coil.

- 2. Welder : Tail end of coil to be welded to the head end of the succeed coil.

- 3. Pre-Cleaning : The strip is degreased to remove oil and dirt from strip.

- 4. Entry looper : Strip is accumulated for continuous running at center section in case of entry section is stopped for welding.

CENTER SECTION

- 5. Cleaning : Electrolytic cleaning and pickling process to remove oil and iron oxide film on the steel surface before plating.

- 6. Plating cell : Strip is coated with zinc by electrolytic process.Coating weight is controlled by quantity of electricity.

- 7. Chemical treatment : Phosphate film is chemically coated on the plated zinc as pre-treatment before painting at customer. Chromating is no more produced since the end of 2006.

- 8. Resin coating : Product V2 and VN (special resin) are resin coated at coater unit and baked at oven until before cooling at cooling unit.

- 9. Oven : Coated resin film is baked by induction heater unit.

- 10. Cooling : Baked strip is cooled down by air cooling system.

DELIVERY SECTION

- Close inspection and winding product coil

- 11. Delivery looper : Accumulate strip for continuous running at center section in case of delivery section is stopped.

- 12. Inspection : Inspect surface of product and take samples for quality testing.

- 13. Tension reel : Wind a product after inspection.

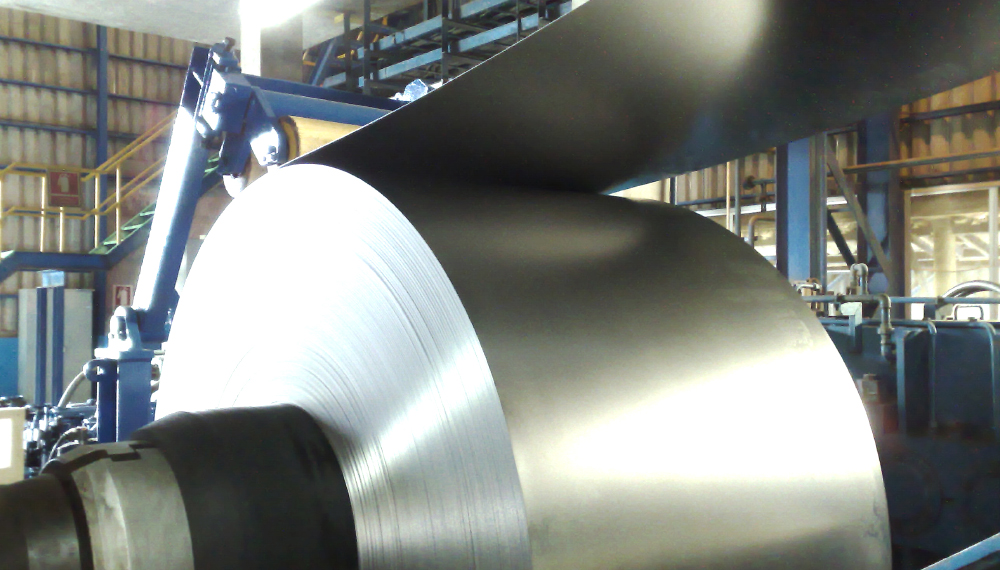

Specification of EGL

Cold Rolled Coil (Raw Material)

เหล็กม้วนรีดเย็น (วัตถุดิบ)

WEIGHT

:

22.7tons max.

OUTER DYNAMETER

:

1,930mm max.

INNER DYNAMETER

:

20inch or 24inch

(508 or 610mm)

(508 or 610mm)

THICKNESS

:

0.27 - 2.3mm

WIDTH

:

700 - 1,550mm

EGL Product

ผลิตภัณฑ์ของ EGL

WEIGHT

:

15tons max.

OUTER DYNAMETER

:

1,850mm max.

INNER DYNAMETER

:

20inch or 24inch

(508 or 610mm)

(508 or 610mm)

EGL Capacity

กำลังการผลิตของ EGL

CAPACITY

:

180,000tons/Year

LINE SPEED

:

90mpm max.

(center section)

(center section)

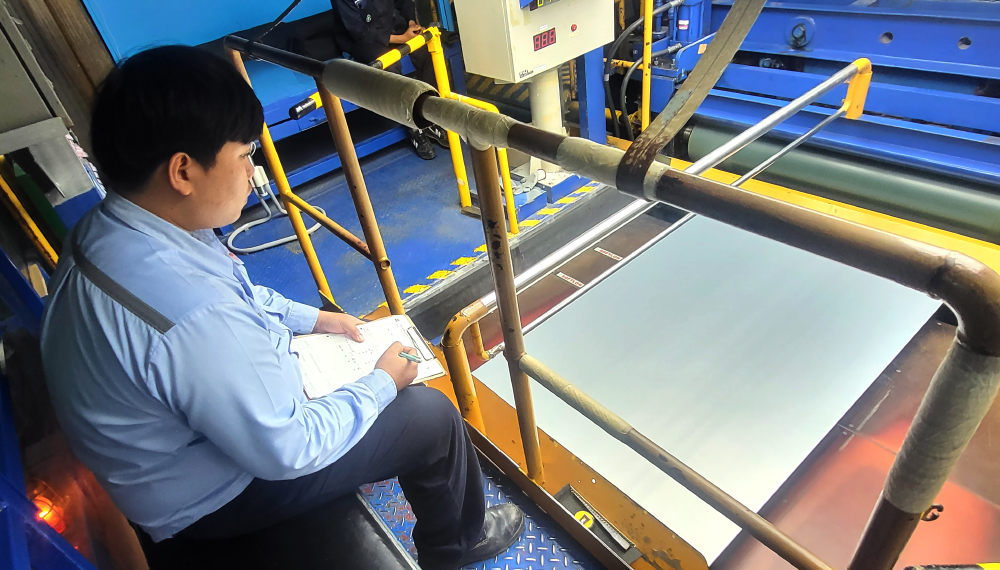

Quality Control & Assurance

Electrogalvanized Steel Sheets

TCS realizes to maintain high standards of quality in both its product and its manufacturing process. This achievement is possible through rigorous quality control process and testing.

All finished products are randomly examined and tested with the high precision instrument, laboratory by highly-skilled specialists to conform with the international control standards.

TCS realizes to maintain high standards of quality in both its product and its manufacturing process. This achievement is possible through rigorous quality control process and testing.

All finished products are randomly examined and tested with the high precision instrument, laboratory by highly-skilled specialists to conform with the international control standards.

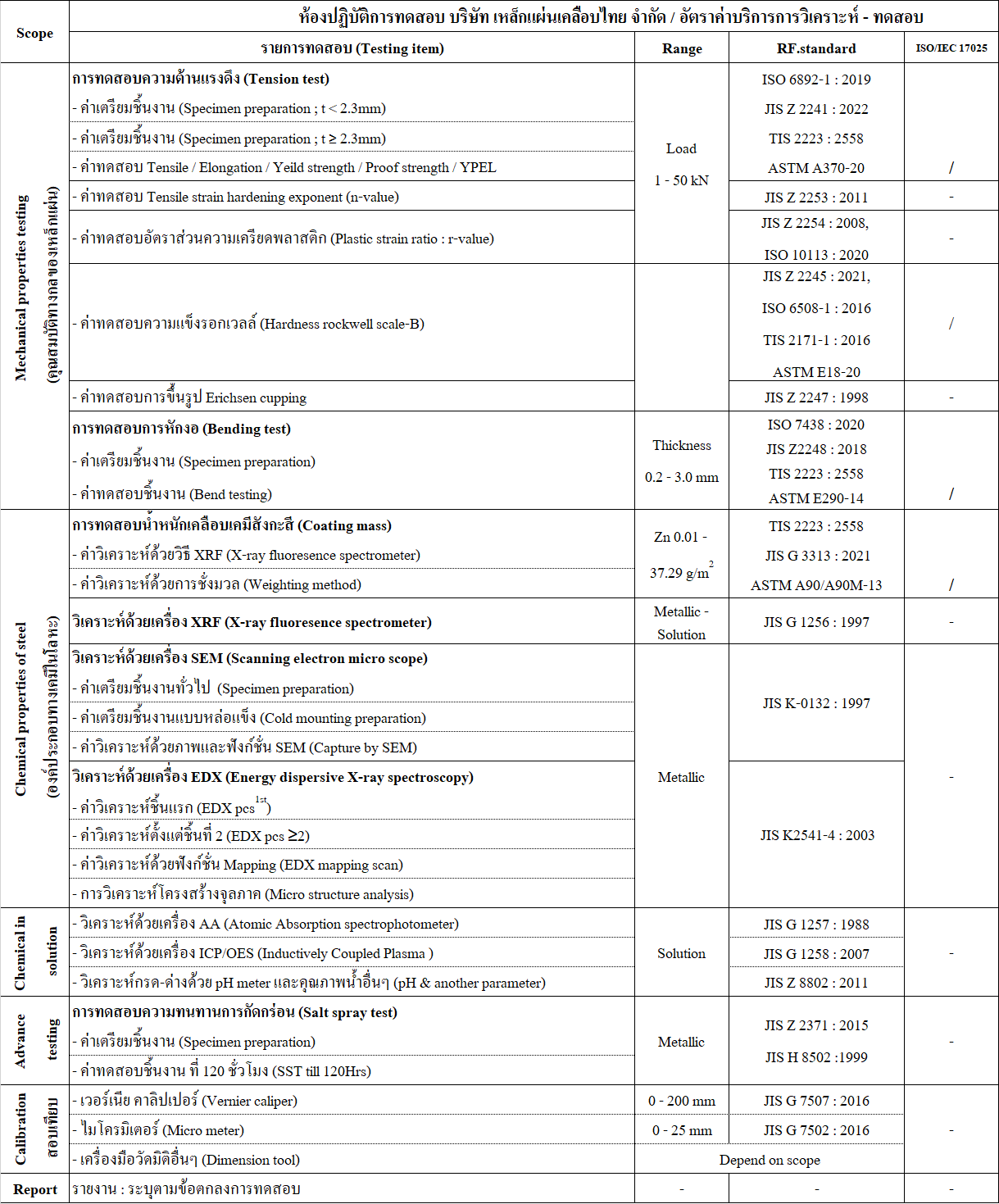

ANA Working Scope

1. Mechanical Properties Test

- Tensile

JIS Z2241, ISO 6892-1, TIS 2172-1, ASTM A370, TIS 2223 - Bend

JIS Z2248, ISO 7438, TIS 2173, ASTM E290, TIS 2223 - HRB

JIS Z2245, ISO 6508-1, TIS 2171-1, ASTM E18, TIS 2223

2. Coating Mass Test

- Coating Mass

JIS G3313, ISO 5002, TIS 2223

3. Crystal Analysis (Micro)

- SEM & EDX

4. Corrosion Resistance

- SST

JIS Z-2371

5. Elemental in Solution

- ICP / OES

JIS G-1258 - AA

JIS G-1257